2D optimization technology

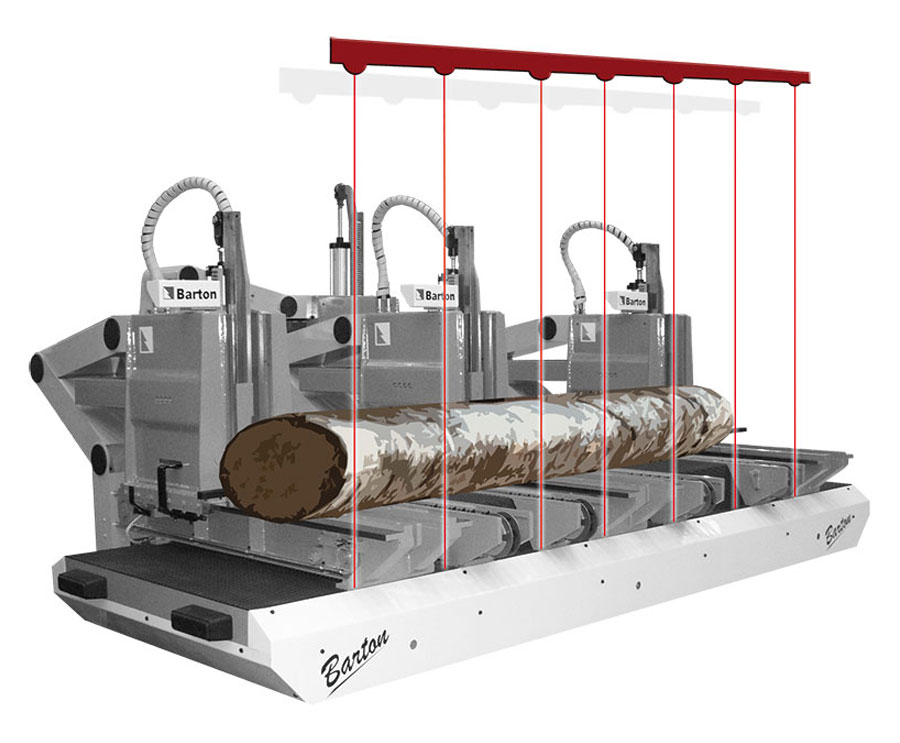

The optimization equipment basically is formed of, a laser array to performance a 2D scanning and of a touch screen terminal (TST).

The alignment of the log is done automatically thanks to the profile data obtained in the 2D Scanning, once the alignment is done, the sawn process get started.

The touch screen terminal of 10.4 in, is located at the control switchboard and is equipped with a USB and Ethernet ports.

The last one enables a remote connexion. The TST can generate up to three operators and register information as: starting and finishing hour, approximate log´s volume processed, downtime, etc.

The Ethernet port, through the use of a modem enables a remote connexion to the TST, either using a conventional land line data or a GPRS line. Using this remote connexion, our technicians can diagnose and solve troubles, reducing this way the downtimes and avoiding costly skilled personnel.

The TST is user friendly and offers several sawn patterns, in a fast and intuitive way. The sawn patterns basically can be classified in:

BOARD MODE.

MULTIBOARD MODE.

EXPLODED MODE.